Top 10 Best Uses of 304 Steel Tube for Various Applications?

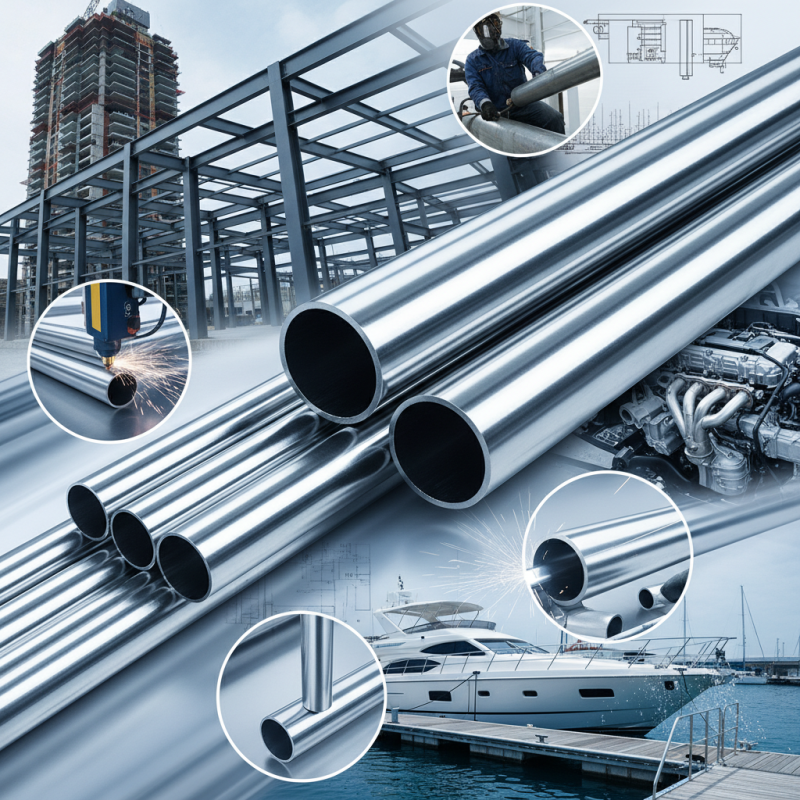

The versatility of 304 Steel Tube makes it a popular choice across various industries. According to John Adams, a leading expert in metal fabrication, "304 Steel Tube provides strength and flexibility that few materials can match." This combination of properties is essential for many applications, from construction to automotive.

In construction, 304 Steel Tube is often used for frameworks and supports. Its resistance to corrosion ensures longevity even in harsh environments. Similarly, the automotive industry relies on this material for exhaust systems and structural components. However, there are challenges, such as needing precise cutting techniques for optimal performance.

Not all applications may realize the full potential of 304 Steel Tube. For instance, in the marine sector, corrosion can still be an issue if not treated properly. Each application requires careful consideration of the tube's characteristics, emphasizing the importance of expert knowledge. Reflecting on these factors can lead to better practices and innovations.

Overview of 304 Steel Tube Characteristics and Benefits

The 304 steel tube is known for its versatility. It boasts excellent corrosion resistance, making it ideal for a range of applications. With a high nickel and chromium content, this stainless steel offers durability. Its non-reactive nature is beneficial in food and pharmaceutical industries. The strength of 304 steel also ensures structural integrity in various constructions.

Tips: When selecting a 304 steel tube, consider the exact specifications needed for your project. Assess your environment, as exposure to certain chemicals may affect performance. Always consult with a professional to understand the material’s properties fully.

If you plan to use 304 steel tube outdoors, remember it can still corrode over time. This makes regular maintenance essential to preserve its appearance and functionality. Adjustments during fabrication may be required to fit unique needs. Keep in mind that while 304 is versatile, it may not suit every situation. Always have a fallback plan for critical applications.

Top 10 Best Uses of 304 Steel Tube for Various Applications

| Application |

Characteristics |

Benefits |

| Construction |

Corrosion-resistant, strong |

Durability, long lifespan |

| Automotive |

High tensile strength, lightweight |

Increased fuel efficiency, safety |

| Food Processing |

Non-reactive, easy to clean |

Hygienic, prevents contamination |

| Oil and Gas |

Resistant to high pressure |

Reliable performance, safety |

| Medical Equipment |

Biocompatible, non-corrosive |

Patient safety, longevity |

| Furniture Design |

Stylish, sturdy |

Aesthetic appeal, durability |

| Marine Applications |

Resistant to saltwater corrosion |

Longevity in harsh environments |

| Architecture |

Versatile, modern look |

Unique design possibilities |

| HVAC Systems |

Heat resistant, insulating |

Efficiency, energy-saving |

| Transportation |

Lightweight, strong |

Improved handling, safety |

Common Applications of 304 Steel Tube in Construction Projects

304 steel tube has numerous applications in construction projects. Its corrosion resistance and formability make it an ideal choice for various structural components. In commercial buildings, 304 steel tubes are often used for railings, columns, and frames. These components not only add strength but also enhance the aesthetics of a structure.

In residential construction, 304 steel tubes are employed in plumbing systems and support structures. Their ability to withstand harsh environments makes them suitable for outdoor applications. However, the cost can be a concern. While they offer durability, the price point may not always fit within limited budgets. This is a common issue that contractors face.

In infrastructure, 304 steel tubes serve critical roles in bridges and tunnels. Their strength ensures safety and reliability. Yet, using them inefficiently can lead to waste. Proper planning is essential. Choosing the right grade and size is vital for project success. Miscalculations can result in increased costs and delays. Making informed decisions during the selection process is crucial.

Utilizing 304 Steel Tube in Industrial Manufacturing Processes

304 steel tube is a versatile material widely used in industrial manufacturing. Its corrosion resistance makes it suitable for various applications. This steel is often found in construction projects, where its strength and durability are essential. It can handle harsh environments, ensuring long-lasting structures.

In processing plants, 304 steel tubes are essential. They transport fluids and gases efficiently. These tubes maintain integrity under pressure, which is crucial in manufacturing. However, using this material requires careful consideration. Sometimes, it may not be the most cost-effective option. Alternatives like carbon steel might serve specific industries better.

Many manufacturers appreciate the ease of fabrication with 304 steel tubes. They can be welded, machined, and formed without difficulty. Yet, this process can also lead to inconsistencies. It’s vital to ensure quality control throughout manufacturing. Addressing the challenges of 304 steel tube usage can lead to improved products and applications.

Innovative Uses of 304 Steel Tube in Automotive Design

The automotive industry constantly seeks innovation through materials like 304 steel tube. This material, known for its corrosion resistance and excellent strength, is ideal for various components in vehicle design. The Society of Automotive Engineers reports a growing trend in using stainless steel tubes in exhaust systems, reducing weight while enhancing durability.

In structural applications, 304 steel tubes offer significant advantages. They are often used in chassis and frameworks. The weight-to-strength ratio is vital. According to industry analyses, adopting lighter materials can improve fuel efficiency by up to 10%. However, not all designs maximize this potential. Some engineers overlook the balance between weight reduction and structural integrity.

Another innovative use is in safety features. Tubes made of 304 stainless steel can enhance crash protection. However, integrating these materials can be challenging. Designers must ensure the tubes do not compromise other systems. There are ongoing debates about cost versus performance. Steel tubes may add initial costs, but their longevity can outweigh these factors. Despite the hurdles, the automotive sector continues to explore the benefits of this versatile alloy.

304 Steel Tube in Household and Commercial Furniture Design

304 stainless steel tubes have become increasingly popular in both household and commercial furniture design. Their durability offers a seamless integration into furniture pieces. Designers appreciate the aesthetic appeal of this material, as it provides a sleek and modern look.

In residential settings, 304 steel tubes enhance the structure of dining tables and chairs. The strength of the material ensures longevity. It can also be used for shelving units, combining style and function. However, the cost can be a consideration for some. While it’s a robust choice, budget constraints might limit its use.

In commercial spaces, 304 steel tubes appear in counter designs and display fixtures. This material can withstand daily wear, adding to its practicality. Yet, some may find it can feel too industrial for certain themes. Finding the balance between style and functionality may require additional thought. Exploring different finishes might offer solutions for those who seek warmth in their designs.